Why Is XHHW-2 Electric Wire Becoming the Preferred Choice for Modern Electrical Systems?

2025-12-02

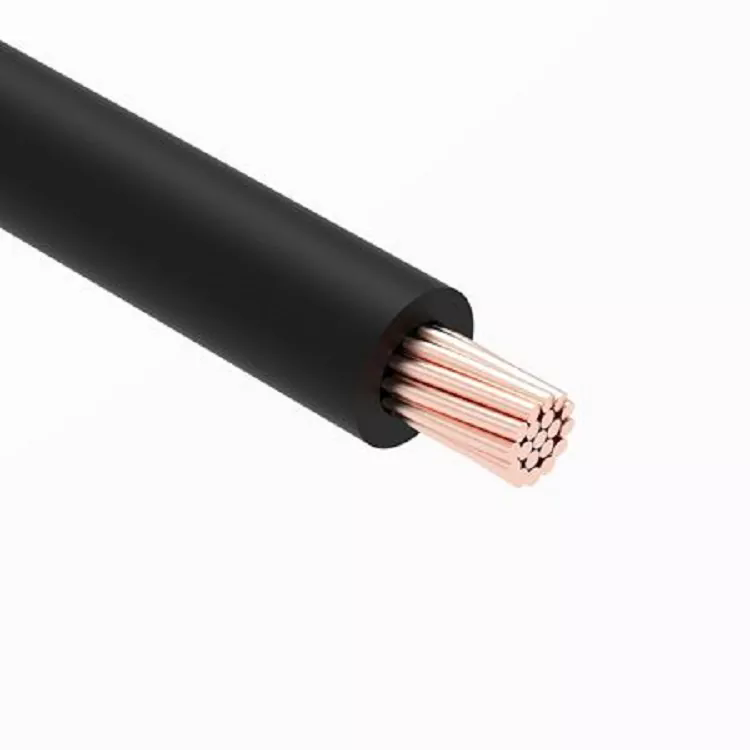

XHHW-2 electric wire has become one of the most widely adopted options in residential, commercial, and industrial electrical installations due to its durability, heat resistance, and versatility. Known for its cross-linked polyethylene (XLPE) insulation and high temperature rating, this wire is engineered to deliver long-term safety and performance in demanding environments.

How Does the Construction of XHHW-2 Wire Enhance Performance?

Understanding how XHHW-2 wire is built helps clarify why it is consistently preferred for high-integrity electrical systems. Its engineered insulation, carefully selected conductor materials, and UL-listed compliance contribute directly to its reliability.

Key Product Parameters

| Parameter | Specification |

|---|---|

| Conductor Material | Copper or Aluminum (AA-8000 series) |

| Insulation Type | XLPE (Cross-linked Polyethylene) |

| Voltage Rating | 600V |

| Temperature Rating (Wet & Dry) | Up to 90°C |

| Flame Test Compliance | Meets FT1 or equivalent |

| Sunlight Resistance | Yes (marked SR) |

| Oil & Gas Resistance | Marked as Gasoline & Oil Resistant II |

| Typical Sizes | 14 AWG – 1000 kcmil |

| Applications | Conduit, raceways, service feeders, industrial panels |

How Does Insulation Improve Safety?

The XLPE insulation is chemically cross-linked to create a tighter molecular structure. This process results in insulation that withstands higher temperatures, resists abrasion, and reduces risks associated with thermal degradation. The insulation’s strength also allows for reduced installation damage and better long-term electrical stability.

How Does the Temperature Rating Influence System Efficiency?

With a 90°C temperature rating, XHHW-2 wire can handle higher current loads without compromising performance. This enables more efficient energy transmission and reduces heat loss, especially in densely packed conduits common in large buildings or industrial facilities.

How Is XHHW-2 Wire Applied Across Multiple Industries?

The adaptability of XHHW-2 wire makes it suitable for a broad range of electrical environments. Its consistent performance in both wet and dry locations supports a variety of installations that require long-lasting insulation reliability.

How Do Installers Benefit in Residential and Commercial Buildings?

In homes, offices, malls, and commercial buildings, XHHW-2 wire is often selected for feeders and branch circuits because it maintains structural integrity even under continuous load. Its sunlight-resistant properties also allow for outdoor routing when necessary.

How Does Industrial Application Demonstrate Its Durability?

Manufacturing facilities, data centers, refineries, and high-temperature machine zones rely heavily on XHHW-2 wire due to its resilience in harsh environments. XLPE insulation performs well around chemical exposure, mechanical vibrations, and extreme temperature fluctuations.

How Does It Support Renewable Energy and Infrastructure Expansion?

Solar power systems, wind turbines, and electric vehicle charging centers require wires that can tolerate environmental stress and extended operational hours. The thermal stability and insulation strength of XHHW-2 make it ideal for emerging sustainable-energy installations, which are rapidly expanding worldwide.

How Will Future Trends Influence XHHW-2 Wire Development?

As electrical systems evolve, XHHW-2 wire is expected to gain further relevance. Demand is rising in urban developments, energy-efficient buildings, and digital infrastructure projects.

How Are Energy-Saving Regulations Driving Changes?

Governments increasingly require safer, more efficient wiring methods. XHHW-2 wire already fulfills numerous compliance standards, positioning it as a wire type aligned with future-focused energy codes and electrical safety regulations.

How Will Technological Advancements Transform Its Role?

Innovations in XLPE insulation, conductor purification, and automated manufacturing enhance wire precision and durability. Trends indicate that future XHHW-2 cables may incorporate:

-

Reduced dielectric loss rates

-

Improved environmental resistance

-

Enhanced fire-retardant properties

-

Lighter but stronger conductor alloys

These improvements will further solidify XHHW-2 wire’s suitability for smart buildings, AI-powered industrial automation systems, and advanced energy storage networks.

Common Questions About XHHW-2 Wire

Q1: How does XHHW-2 differ from THHN wire in performance and application?

A1: XHHW-2 wire uses XLPE insulation, which allows it to withstand higher temperatures and provides better resistance to moisture, abrasion, and chemicals. In comparison, THHN uses PVC/Nylon insulation, which may not perform as well in wet or high-heat environments. XHHW-2 is therefore preferred for long-term installations, outdoor routing, and industrial conditions where reliability under stress is crucial.

Q2: How should installers choose between copper and aluminum XHHW-2 conductors?

A2: Copper offers higher conductivity and better mechanical strength, making it ideal for smaller gauge circuits or areas requiring compact installations. Aluminum provides a lighter and more cost-effective alternative for larger feeder cables where weight reduction and economic efficiency are prioritized. Both meet electrical code requirements when installed correctly, and the choice depends on load calculations, conduit fill, and project budget.

Conclusion

XHHW-2 electric wire continues to shape the future of electrical installations through its robust insulation, high thermal tolerance, and versatile performance across industries. Its ability to withstand harsh conditions and maintain reliable conductivity makes it a preferred option for modern building infrastructure, renewable energy systems, and high-demand industrial environments. As electrical technologies advance, XHHW-2 wire is positioned to remain a cornerstone of safe and efficient power distribution.

Manufacturers such as DAYA provide high-quality XHHW-2 wire engineered to meet stringent quality standards for global markets. For project inquiries or technical specifications, contact us to receive professional support and customized solutions.