What Are the Best Practices for Routing Control Cables in a Panel

2026-01-05

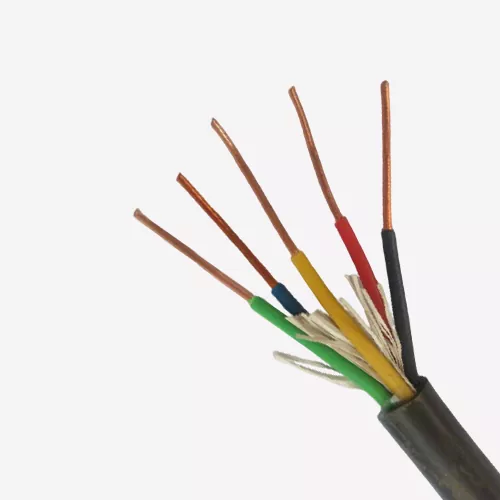

Efficient and reliable panel assembly is critical for industrial automation, and proper Control Cable routing sits at its core. Poor cable management can lead to signal interference, mechanical damage, and challenging maintenance, ultimately compromising system integrity. At Yilan, we combine engineering expertise with high-performance cabling solutions to ensure your panels are built for durability and peak performance. This guide outlines essential best practices to achieve clean, safe, and compliant cable routing.

Essential Guidelines for Optimal Cable Routing

Following a structured approach from the planning stage prevents common pitfalls. Here are the key practices:

-

Plan and Segregate: Before installation, create a detailed routing plan. Crucially, segregate Control Cables from power cables. Run them in separate trays or with adequate spacing to minimize Electromagnetic Interference (EMI).

-

Use Proper Support: Avoid loose cable runs. Use cable ties, ducting, and clamps to secure cables at regular intervals. This prevents stress on termination points and protects against vibration.

-

Maintain Bend Radius: Always adhere to the cable manufacturer's specified minimum bend radius. Exceeding it can damage internal conductors and shielding, degrading performance.

-

Label Meticulously: Every cable and wire should be clearly labeled at both ends. This is non-negotiable for efficient troubleshooting and future modifications.

-

Implement Strain Relief: Use glands or clamps at panel entry points to prevent axial pull forces from being transferred to electrical terminals, ensuring long-term connection integrity.

Cable Segregation Distance Recommendations

This table provides a quick reference for minimum separation distances under typical industrial conditions to reduce noise coupling.

| Cable Type | Minimum Recommended Separation from Power Cables |

|---|---|

| Analog Signal Control Cables | 200 mm (8 inches) |

| Digital / Communication Control Cables | 150 mm (6 inches) |

| Low-Voltage DC Power Cables | 100 mm (4 inches) |

Control Cable FAQ

Q: What is the single most important rule when routing cables inside a panel?

A: The most critical rule is segregation. Keeping low-voltage signal and control cables physically separated from high-current power cables is paramount to prevent electromagnetic interference (EMI), which can cause erratic signal behavior and data corruption.

Q: How tight is too tight when bending a control cable?

A: A bend tighter than the manufacturer's specified minimum bend radius is too tight. As a general rule, the radius should not be less than 8 times the overall cable diameter for standard cables. For high-flex Yilan cables, refer to the specific datasheet. Violating this radius can permanently compromise the cable's shielding and conductors.

Q: Can I use standard zip ties for all cable bundling?

A: While convenient, standard nylon zip ties can be over-tightened, potentially crushing cable insulation. For permanent installations, use dedicated cable ties with smooth edges or Velcro straps for bundles. In high-vibration environments, consider locking clamps or dedicated cable tie mounts for added security.

Proper Control Cable routing is not merely an aesthetic concern—it's a fundamental engineering practice that ensures system reliability, safety, and ease of maintenance. By adhering to these best practices, you invest in the long-term stability of your automation systems. For projects that demand exceptional performance and durability, partnering with a knowledgeable supplier makes all the difference.

Ready to build a better panel? Contact us at Yilan today. Our technical experts can help you select the ideal Control Cable solutions and provide support to ensure your installation is a success.