Is an Optical (Fiber-Optic) Gyroscope the Future of Precision Navigation?

2025-10-17

Optic gyroscopes—especially fiber-optic gyroscopes (FOGs)—represent a cutting-edge class of rotational sensors that measure angular velocity using light interference rather than moving parts. In precision navigation, aerospace, autonomous systems, and industrial stabilization, they offer superior drift stability, long lifespan, and immunity to mechanical wear.

The core of this article is structured around four major nodes:

-

What is an optic gyroscope and its key technical parameters

-

Why optic gyroscopes matter (advantages, use cases, market trends)

-

How optic gyroscopes work, and how they are evolving

-

Common questions and concluding notes including Jioptik’s offering

What Is an Optical Gyroscope — Key Specifications and Types

An optical gyroscope is a device that detects rotational movement (angular velocity) by using light propagation, typically in optical fibers, exploiting the Sagnac effect. Unlike mechanical gyroscopes, optical gyros have no moving parts, offering higher reliability and lower maintenance.

Among optical gyros, the fiber-optic gyroscope (FOG) is dominant in current applications, though emerging variants like silicon photonic gyros and resonant gyros are under development.

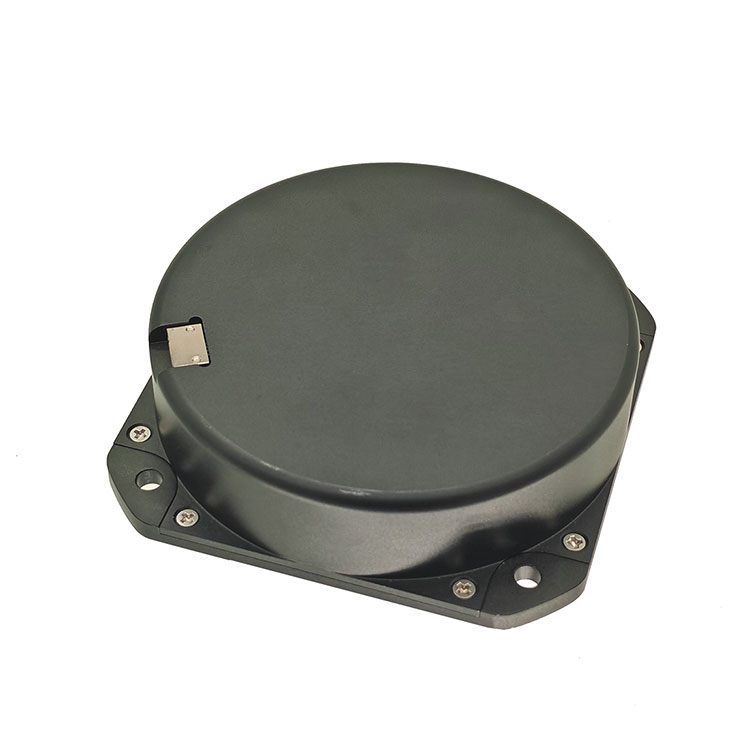

Below is a representative specification table for a high-performance 3-axis fiber-optic gyroscope module:

| Parameter | Typical Value / Range | Notes / Comments |

|---|---|---|

| Bias stability (drift) | ≤ 0.01 to 0.1°/h | High-end tactical/strategic grade |

| Angular Random Walk (ARW) | 0.005–0.05°/√h | Determines noise floor |

| Bandwidth | 100–500 Hz or more | High bandwidth enables fast control |

| Measurement range | ±300°/s to ±2000°/s | Depends on application |

| Power consumption | Few watts (2 W – 10 W) | Module and electronics |

| Size / Weight | Several tens to few hundreds of grams | Compact, but not yet MEMS scale |

| Operating temperature | –40 °C to +85 °C (higher in specialized) | Depends on rugged design |

| Axis count | 1, 2, or 3 | Most common is 3-axis |

| Interface | SPI, RS-422, Ethernet, etc. | For integration into system |

| Calibration stability | Long-term drift <1% per 1,000 hours | Critical for inertial systems |

These numbers are indicative; real products can vary. For instance, EMCORE’s EG-120 is an ultra-compact closed-loop FOG module boasting low power, small size, and stable performance.In designing or selecting a gyroscope, factors such as drift, ARW, bandwidth, stability, size/weight, and interface compatibility are critical.

Other types of optical gyros worth noting include:

-

Resonant (ring-laser) gyroscopes — use a ring laser cavity with counter-propagating beams.

-

Chip-based (silicon photonic) gyroscopes — emerging designs that integrate optical paths on-chip to shrink size and cost.

-

Hybrid / passive modulation gyros — recent academic advances push for passive phase biasing or resonant enhancement to reduce power and complexity.

With this baseline, the article next explores why optic gyros are crucial in modern systems.

Why Optical Gyroscopes Matter

Key Advantages over Mechanical and MEMS Gyros

-

No moving parts & zero wear: Optical gyroscopes lack rotating or vibrating mechanical components, removing failure sources due to friction or mechanical drift.

-

Low drift & high stability: Drift over time is drastically reduced compared to mechanical gyros. This makes them ideal for long-term inertial navigation without frequent recalibration.

-

Immunity to electromagnetic interference (EMI): Light-based sensing is largely unaffected by magnetic fields or electrical noise, a strong benefit in harsh environments.

-

High bandwidth and fast response: Optical systems can respond rapidly, suitable for dynamic stabilization and control loops.

-

Scalability and modular design: By adjusting coil length and fiber geometry, performance can be tuned for different grades.

-

Long lifetime & reliability: Because there is no mechanical wear, systems can run continuously with minimal maintenance.

In contrast:

-

MEMS gyroscopes (vibrating structure gyros) are compact and low-cost but suffer from bias instability, noise, and limited dynamic range.

-

Mechanical spinners are obsolete in most precision applications due to friction, drift, and limited reliability.

-

Ring laser gyros are high-performance but face challenges like laser mode “lock-in” at low speeds.

Thus, for medium to high accuracy navigation, especially in GNSS-denied or harsh conditions, optical gyros are the technology of choice.

2.2 Application Scenarios

-

Inertial Navigation Systems (INS) & GNSS-Aided Navigation: In aircraft, missiles, submarines, and spacecraft, optical gyros provide rotational rate info critical for attitude and heading reference.

-

Unmanned Aerial Vehicles (UAVs) / Drones: High-precision stabilization and guidance, especially in autonomous flights and GPS-challenged environments.

-

Marine & Underwater Navigation: Submarines, autonomous underwater vehicles (AUVs), and ships benefit from drift-free, EMI-immune turning sensors.

-

Stabilization and Gimbals: Camera platforms, turret stabilization, and optical systems that require precise orientation control.

-

Industrial Robotics and Automation: Motion systems, factory automation, and precision positioning in industrial settings.

-

Aerospace & Satellite Attitude Control: Reaction to small angular deviations in spacecraft, satellites, and space probes.

-

Future autonomous vehicles and advanced driver assistance systems (ADAS): As demands for robust navigation increase, optical gyros may augment or exceed MEMS gyros in performance.

2.3 Market Trends and Growth

-

The global fiber optic gyroscope market is expected to expand significantly, with estimates ranging from a 4 % to 14 % compound annual growth rate (CAGR) depending on forecast horizon.

-

One estimate values it at USD 1.90 billion in 2025, growing to USD 4.49 billion by 2035 (CAGR ~14.2 %).

-

Another forecast by Mordor Intelligence puts the 2025 market at USD 1.19 billion and expects growth to USD 1.47 billion by 2030 (CAGR ~4.32 %).

-

Growth drivers include defense modernization budgets, expansion of autonomous systems, demand for navigation in GPS-denied environments, and miniaturization trends.

-

A strong trend is miniaturization and photonic integration, pushing optical gyros toward chip-scale implementations.

-

Integrated photonics and silicon-waveguide approaches are expected to drive down cost, size, and power, enabling broader adoption beyond military and aerospace sectors.

Given these compelling advantages and expanding market, the next node explores how optical gyros work and how they are evolving toward next-generation designs.

How Optical Gyroscopes Work & Evolve

Underlying Principle: The Sagnac Effect

At the heart of any optical gyroscope is the Sagnac effect, wherein two beams of light traveling in opposite directions around a loop will experience a phase difference if the loop is rotating. The path difference (or time difference) between the beams is proportional to the angular rate.

In a FOG, a coherent light source (laser) emits two light beams that are split and sent in clockwise and counter-clockwise directions through a fiber coil. Upon returning, interference between the two beams reveals the rotational phase shift, which can be converted to angular velocity.

If the assembly rotates, one beam’s effective path becomes longer relative to the other, producing a measurable interference shift.

Architecture and Signal Processing

Key modules of a typical FOG system include:

-

Light source (laser or broadband source)

-

Beam splitter / coupler

-

Optical fiber coil

-

Phase modulator / biasing (open-loop or closed-loop)

-

Photodetector(s) to capture the interference signal

-

Signal processing electronics / FPGA / DSP

-

Calibration and compensation algorithms

-

Open-loop vs closed-loop operation: In open-loop mode, the phase shift is measured directly, but linearity and stability are limited. Closed-loop designs apply a feedback correction (compensating phase) to maintain quadrature, improving linearity, dynamic range, and drift performance.

-

Biasing and modulation: Many systems use phase modulators or polarization-based biasing techniques. Some advanced research explores fully passive biasing (no active modulation) to reduce power and complexity.

-

Temperature compensation and calibration: Fiber length, refractive index, and electronics drift require compensation. Calibration is often done using reference rotation, internal temperature sensors, and periodic recalibration.

-

Digital signal processing and filtering: Noise suppression, drift correction, error calibration, and compensation for fiber non-linearities are essential.

3.3 Evolution & Cutting-Edge Trends

-

Integration and Photonic Chips: New designs leverage silicon photonics to embed loop waveguides and couplers on-chip, drastically reducing size, cost, and fiber length while maintaining sensitivity.

-

Hollow-core fiber and low-loss fibers: To reduce attenuation and enhance sensitivity, new fiber technologies are being explored.

-

Passive dual-quadrature or multi-quadrature schemes: Recent academic designs use non-reciprocal polarization to achieve multiple bias points without active modulation.

-

Quantum-enhanced gyroscopes: Research in entanglement and squeezed states aims to exceed classical noise limits using quantum optical techniques.

-

Digital twin and lifecycle modeling: Some proposals use digital twins to simulate fiber behavior, thermal drift, and degradation over time for better predictive calibration.

-

Miniaturization for mass-market adoption: As optical gyros shrink, they become viable in consumer electronics, automotive, robotics, and compact UAVs.

These developments push optical gyros beyond legacy high-end uses into broader markets.

Frequently Asked Questions & Concluding Remarks

FAQ (Common Questions)

Q1: What is the difference between a fiber-optic gyroscope and a ring laser gyroscope?

A1: A fiber-optic gyroscope uses a passive fiber optic coil and measures the Sagnac-induced phase difference in counter-propagating light beams, while a ring laser gyroscope contains an internal laser cavity with counter-propagating laser modes. Ring lasers can achieve high sensitivity but may suffer from mode lock-in at low rates and complexity in stabilization. In contrast, FOGs are more robust, simpler in maintenance, and immune to lock-in in most designs.

Q2: How is bias drift (drift error) managed in optical gyroscopes?

A2: Bias drift arises from temperature drift, fiber aging, electronics drift, and environmental changes. Mitigation methods include temperature stabilization, careful fiber packaging, calibration (internal and external), closed-loop feedback correction, algorithmic compensation, and use of highly stable components. Regular recalibration and drift tracking allow long-term stability.

Closing & Brand Note

Optic gyroscopes are at the forefront of high-precision rotational sensing, offering unmatched drift stability, reliability, and adaptability. From aerospace and defense to autonomous systems and emerging consumer robotics, their importance will only grow as integration and miniaturization progress. As evolving trends like photonic integration, passive biasing schemes, and even quantum enhancements mature, optical gyros will push the boundary of motion sensing.

Among advanced suppliers, Jioptik is committed to delivering tailored optic gyroscope solutions with high performance, custom calibration, and integration support. For inquiries about product options, customization, or technical consultation, contact us to connect with the Jioptik support and engineering team.