How To Prevent the Commmon Failure Modes of Flexible Copper Connectors?

2025-09-17

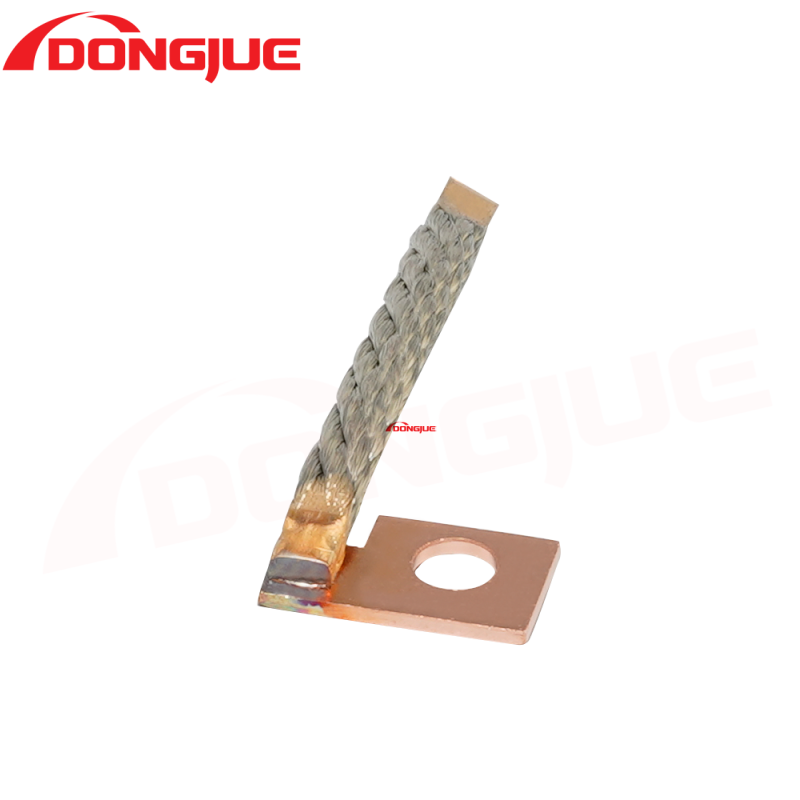

Flexible Copper Connectors are critical components in electrical systems, ensuring reliable conduction and mechanical flexibility. At our factory, we specialize in providing high-quality Flexible Copper Connectors that meet industry standards and deliver long-term performance. In this guide, we will share practical strategies to prevent common failure modes and introduce our product specifications.

Understanding Common Failure Modes

Flexible Copper Connectors can fail due to mechanical stress, corrosion, overheating, or improper installation. Our engineers at Dongjue have identified the following key failure modes:

1. Thermal fatigue caused by repeated heating and cooling cycles

2. Corrosion due to exposure to moisture or chemical environments

3. Mechanical loosening from vibration or improper torque

4. Electrical resistance increase from oxidation or poor contact

Product Specifications

Our Flexible Copper Connectors are designed with high conductivity, flexibility, and corrosion resistance. The following table summarizes our main product parameters:

| Parameter | Specification |

| Material | High-purity electrolytic copper |

| Temperature Range | -40°C to 150°C |

| Rated Current | Up to 500A |

| Voltage Rating | 600V |

| Flexibility | Highly flexible braid design |

| Surface Treatment | Tin-plated or silver-plated options |

Preventive Measures

To extend the service life of Flexible Copper Connectors and prevent common failure modes, our factory recommends the following measures:

1. Regularly inspect connectors for signs of wear, corrosion, or discoloration.

2. Ensure proper torque during installation to avoid mechanical loosening.

3. Use protective coatings or insulation in corrosive environments.

4. Maintain operating temperatures within the specified range to reduce thermal fatigue.

5. Install vibration-damping supports where mechanical movement is significant.

Dongjue has integrated these measures into our manufacturing and testing processes, ensuring our connectors meet stringent quality standards.

FAQs About Flexible Copper Connectors

Q1: How can I reduce the risk of thermal fatigue in Flexible Copper Connectors?

A1: Our factory recommends using connectors rated for the specific operating temperature of your system. Regular monitoring and replacing connectors showing signs of discoloration or deformation are crucial. Dongjue connectors are designed with flexible braids to evenly distribute heat and minimize stress.

Q2: What is the best method to prevent corrosion in Flexible Copper Connectors?

A2: Applying a protective tin or silver plating can significantly reduce oxidation. Additionally, keeping connectors in a dry and chemically stable environment helps. Our team at Dongjue provides connectors with surface treatments optimized for harsh conditions, ensuring long-term performance.

Why Choose Our Flexible Copper Connectors

Our factory takes pride in delivering high-quality products that combine reliability, flexibility, and safety. Our connectors are widely used in industrial and commercial applications. By following our preventive guidelines, our customers enjoy extended service life and reduced maintenance costs.

At Dongjue, our team continuously monitors product performance and implements improvements based on customer feedback. Our commitment to quality ensures that every Flexible Copper Connector meets rigorous standards. Protect your electrical systems with our premium Flexible Copper Connectors. For more information and to place an order, contact Zhejiang Dongjue Cable Co., Ltd. today. Our experts are ready to provide professional guidance and support for your projects.